Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Brand: XL

Place Of Origin: China

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Certificate: ISO9001

Port: Shanghai

Payment Type: T/T,Paypal

Incoterm: FOB

High Temperature Furnace: Revolutionizing Advanced Industrial Manufacturing

In the dynamic realm of industrial manufacturing, the standards for equipment and materials continue to soar. With technological progress, the pursuit of precision and efficiency becomes paramount. Addressing this challenge head-on is the high temperature furnace, an engineering marvel that is reshaping the landscape of metal processing.

The Vital Role of Tungsten & Molybdenum

Amidst these high-temperature domains, two elements emerge as champions: tungsten and molybdenum. Their capacity to endure intense heat while preserving structural integrity renders them irreplaceable within these furnaces.

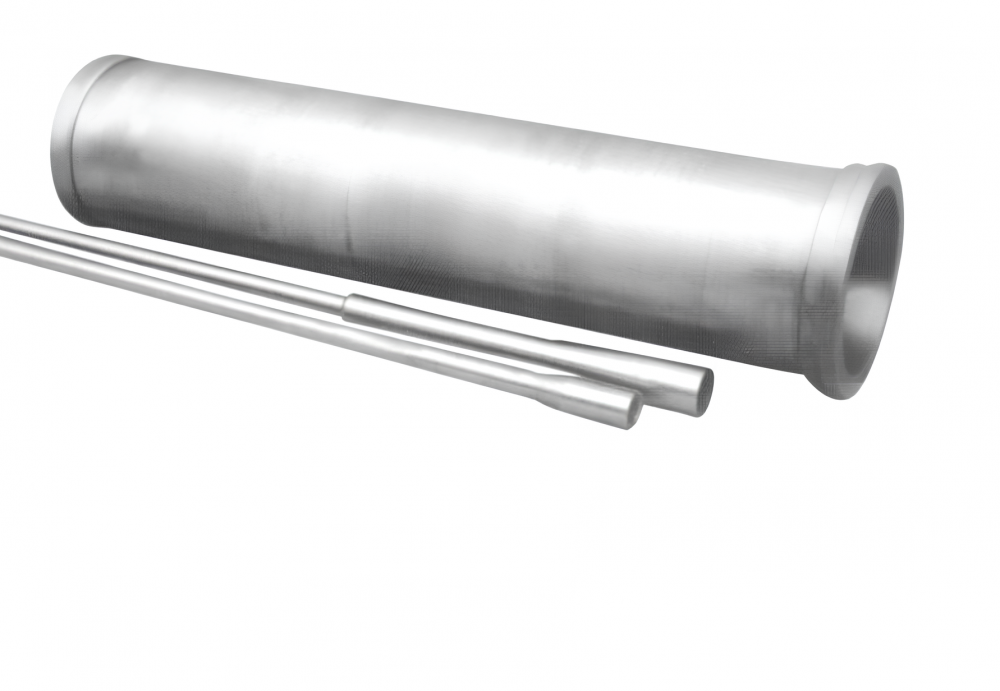

Containers: Tungsten and molybdenum, owing to their high melting points, take center stage in crafting containers that house materials during processing. These containers assure uniform heating and safeguard materials from external contaminants.

Heat Insulation Shields: In environments where temperature uniformity is paramount, shields based on tungsten and molybdenum play a pivotal role in upholding consistent heat levels, ensuring the furnace's interior remains at an optimal temperature.

Heating Elements: At the core of the furnace, heating elements often harness these metals. Their efficient heat conduction and durability guarantee the furnace's optimal operation.

Sticks and Trays for Heat Treatment: For processes demanding prolonged exposure to heat, tungsten and molybdenum sticks and trays prove invaluable. They furnish a stable platform, guaranteeing uniform heat exposure throughout the treatment.

Applications in HIP, Quartz Melting, and More: Whether it involves hot isostatic pressing, where materials endure both heat and pressure, or the precise craft of quartz melting, tungsten and molybdenum consistently stand as top choices.

Customized Product Specifications

Acknowledging the distinct requirements of each industrial application, we take pride in offering tailored solutions that align precisely with your needs. Our approach is far from one-size-fits-all; instead, we engage closely with our clients, comprehending their unique demands, and fabricating products that seamlessly align with their objectives.

Partnership for Excellence

Our commitment transcends mere product provision. We consider ourselves partners in your manufacturing odyssey. Whether it's assisting in material selection or brainstorming solutions for intricate challenges, our team stands by your side at every juncture.

Conclusion

The high temperature furnace, fortified by the potency of tungsten and molybdenum, signifies the realm of possibilities within industrial manufacturing.

As we gaze into the future, it's tools like these that will illuminate the path, propelling efficiency, precision, and innovation in an ever-demanding industrial landscape. Embark on this journey with us, and together, let's forge a route to unrivaled manufacturing excellence.

Incorporating Tungsten Heavy Alloys, Shielding Parts, Balance Weight Materials, and Counterweight Materials into your manufacturing arsenal ensures you're equipped for excellence in every endeavor.

Product Categories : Tungsten Heavy Alloys > Shielding Parts

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.